Curious Kids is a series for children of all ages. If you have a question that you would like an expert to answer, please send it to Curiouskidsus@theconversation.com.

How do they build things like tunnels and bridges underwater? – Helen, age 10, Somerville, Massachusetts

When I was a kid, I discovered a Calvin and Hobbes comic strip that raised one of my burning questions: How do they know the maximum loads on bridges? Calvin’s father tells him (falsely), “They’re going to run over it with bigger and bigger trucks until it breaks down.” Then they weigh the last truck and rebuild the bridge.”

A few decades later I am a geotechnical engineer. This means that I participate in all construction projects that involve land. Now I know the real answers to things people wonder about infrastructure. Often, like Calvin’s father, they think about things from the wrong direction. Engineers typically do not determine the load limit on a bridge; instead, they build the bridge to carry the load they expect.

The same goes for another question I hear every now and then: how do engineers build things underwater? Actually, they don’t normally build things underwater; instead they build things that then end up underwater. This is what I mean.

Underground construction, underwater

When you build underwater, you sometimes really build underground. It’s not about the water you see on the surface, it’s about what surrounds the actual structure you’re building.

If there’s rock or dirt all around what you’re building, it’s usually considered an underground structure – even if there’s a layer of water above it and that’s all you see from above.

Underground structures usually use powerful tunnel boring machines to excavate soil directly. It is not without reason that this machine is often called a mole. Like the animal, it creates a tunnel similar to a burrow by digging horizontally through the ground and removing the excavated material behind it. Done with care, this method can successfully build a tunnel through the ground under a body of water that can then be lined and reinforced.

Engineers used this method, for example, to build the Channel Tunnel, a railway tunnel under the Channel that connects England and France.

Although modern machines are quite advanced, this construction method began about 200 years ago with the tunnel shield. Initially, these were temporary support structures that provided a safe space from which workers could dig. New temporary structures were built deeper and deeper as the tunnel grew. As designs improved with experience, the shields were built to be mobile and eventually evolved into the modern tunnel boring machine.

Building on dry land before it falls into place

Some structures will eventually be surrounded by water and rest on a riverbed or ocean floor. Fortunately, engineers have a few tricks up their sleeves for building bridges and tunnels whose components are in direct contact with the water.

Underground construction is dangerous and difficult to access. Dealing with water brings additional challenges. While soil and rock can be pushed aside to create a stable opening, water will always flow in to fill any gaps and must be continually pumped out.

People, materials and machines don’t really work well underwater either. People need a constant air supply. Placing concrete under water is difficult and some materials only work on dry land. And because gas engines rely on air to operate, underwater equipment is very limited.

Some smaller tasks – aligning and connecting pre-built parts of the tunnel or inspecting to make sure the immersion hasn’t damaged anything – are carried out below the waves, but it’s unlikely that most of the construction will doing. Once the structure is in place, ongoing underwater monitoring and assessment takes place.

Since people generally cannot build underwater, there are two options: build the building in the open and move it underwater, or temporarily convert the underwater site into a dry site.

The first option typically involves crews building parts of the structure on dry land and then sinking them into place. For example, the Ted Williams Tunnel in Boston was built in parts in a shipyard. Workers dredged the future path of the tunnel in Boston Harbor, clearing mud and other debris from the way. They then placed the sealed segments along the prepared trench. Once the segments were connected, they opened the ends of the segments to create one long, continuous tube. Finally, the tunnel was covered with earth and rocks. Very little of the construction process actually took place underwater.

In other cases, such as in shallow water, construction workers may be able to build directly from the surface. For example, workers can drive waterfront retaining walls made of sheet steel directly into the ground from a barge, without having to divert the water.

Temporarily clear the water

The second option is to completely solve the underwater problem.

Although creating a dry spot at the bottom of a body of water is difficult, it does have a long history. After leading the sack of Rome in 410 CE, the Visigothic king Alaric died on his way home. To protect his beautiful burial from grave robbers, Alaric’s people temporarily diverted a local river to bury him and his loot in the riverbed before allowing the river to flow again.

Today, a project like this would use a cofferdam: a temporary, watertight enclosure that can be pumped dry to create an open and safe construction site. Once the area is enclosed and drained of water, you are in the realm of regular construction work.

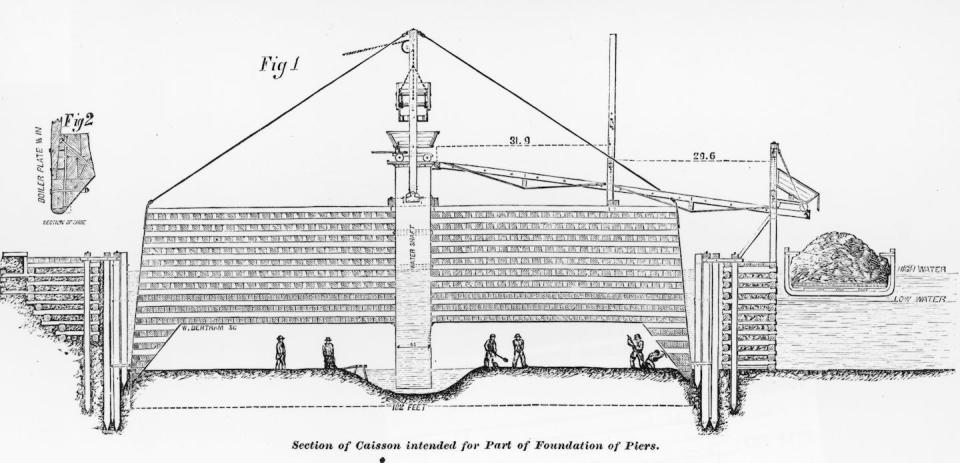

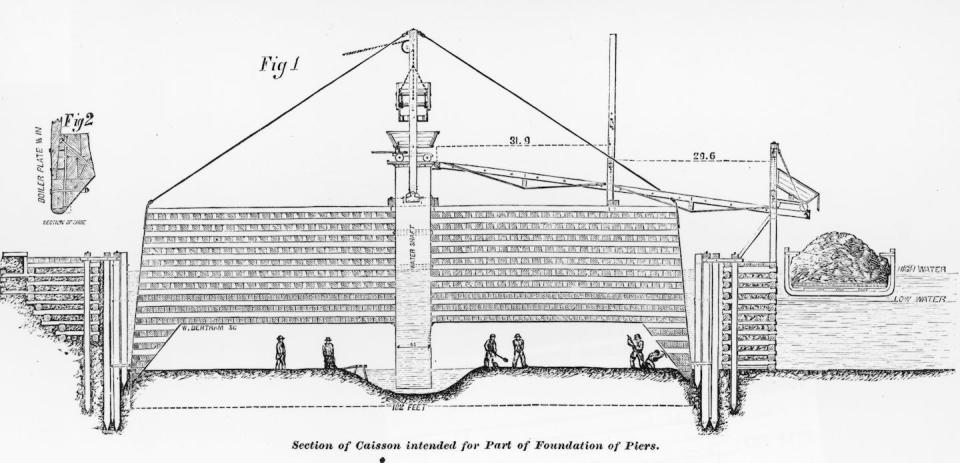

Using a caisson is another way to create a dry area in a location that is typically underwater. A caisson is typically a prefabricated and watertight structure, shaped like an inverted cup, that is sunk into the water by a crew. They keep it pressurized to ensure that water doesn’t flow in. Once the caisson is at the bottom of the water, the air pressure and pumps keep the site dry and construction workers can build inside. The caisson becomes part of the completed structure.

Builders built the piers of the Brooklyn Bridge using caissons. Although the caissons were structurally safe, the pressure difference affected many workers, including chief engineer Washington Roebling. He developed decompression sickness – better known as decompression sickness – and had to resign.

Underwater construction is a complex and difficult task, but engineers have developed several ways to build underwater… often by not building underwater at all.

Hello, curious children! Do you have a question that you would like an expert to answer? Ask an adult to send your question to CuriousKidsUS@theconversation.com. Tell us your name, age and the city where you live.

And since curiosity knows no age limit – adults, let us know what you’re wondering too. We won’t be able to answer all questions, but we will do our best.

This article is republished from The Conversation, an independent nonprofit organization providing facts and trusted analysis to help you understand our complex world. It was written by: Ari Perez, Quinnipiac University

Read more:

Ari Perez does not work for, consult with, own stock in, or receive funding from any company or organization that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.